Customization of complex shapes

Customization of complex shapes

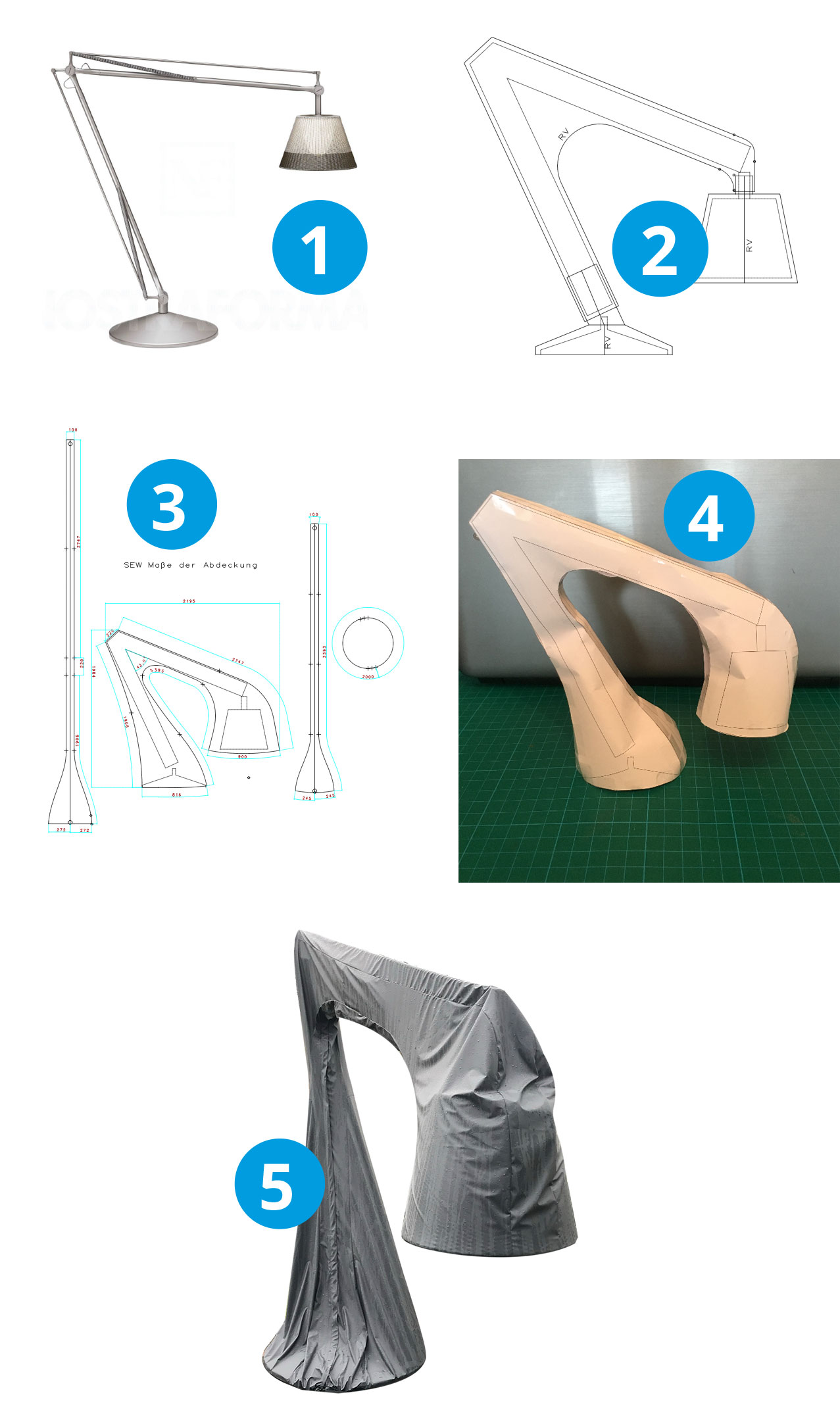

In addition to standard shapes such as rectangular or round covers, complex shapes are sometimes requested. The effort for this is not quite insignificant. At the beginning there is the customer's photo with corresponding dimensions or in the optimal case a technical sketch. Our cutting director first creates a possible shape of the cover on the computer. (Fig. 2) The shape is then agreed with the customer and technically dimensioned (Fig. 3). In some cases, we make a miniature paper sample (picture 4). If everything fits, a CAD plan is created, plotted out 1:1, transferred to the fabric and all the cut parts are cut out. The joining is then done on the ultrasonic welding machine. In this case, a zipper was also incorporated over the entire length, so that the Wettertuete can also be pulled up well.

even complex shapes can be made to measure. The lead time is a bit longer here, because many things have to be considered